Systems Engineering and Electronics ›› 2023, Vol. 45 ›› Issue (5): 1277-1285.doi: 10.12305/j.issn.1001-506X.2023.05.03

• Electronic Technology • Previous Articles

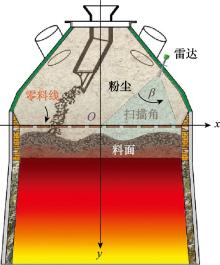

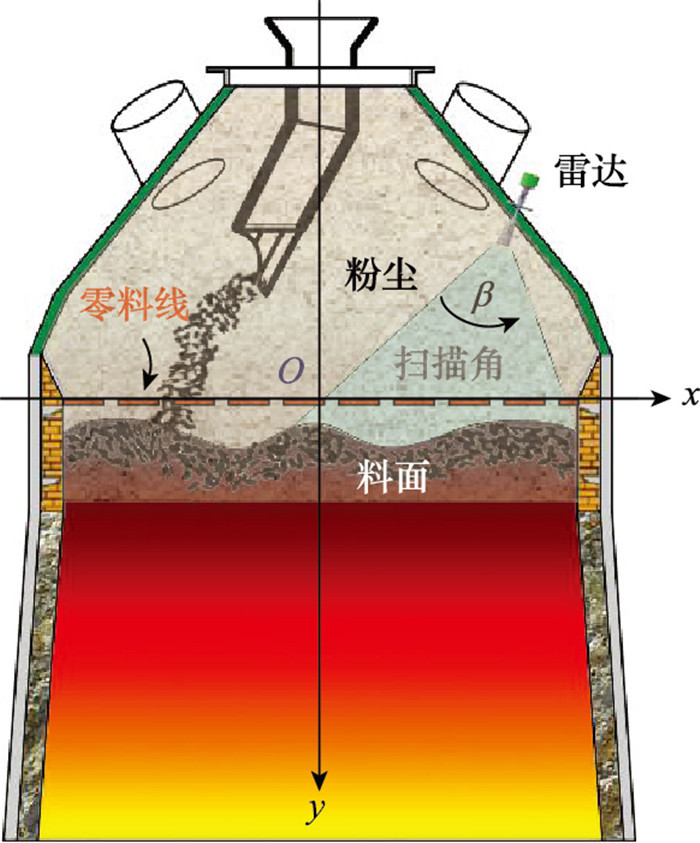

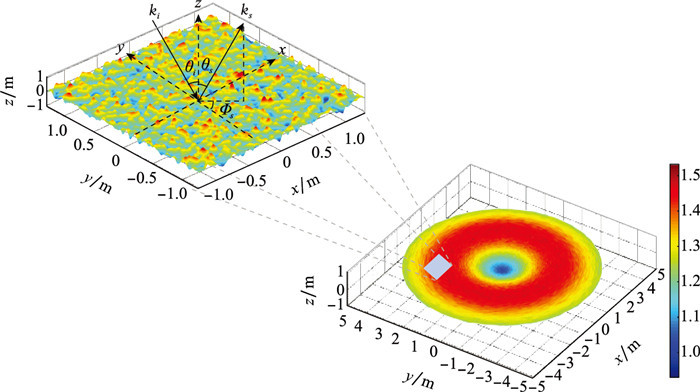

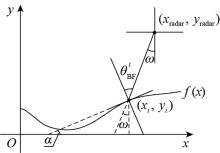

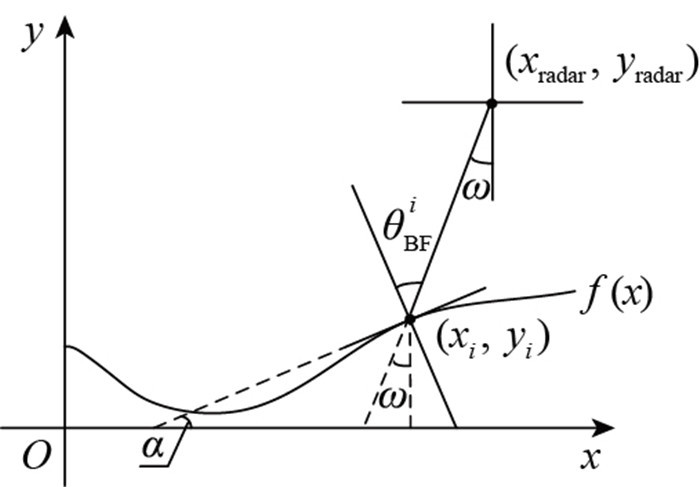

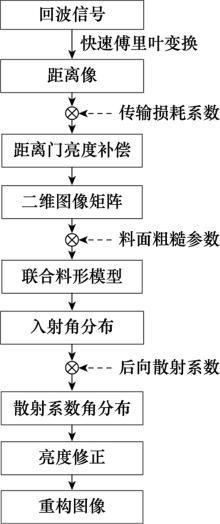

Scattering characteristics modeling and imaging of blast furnace burden surface in dusty environment

Qing YU1,2, Qingwen HOU1,2, Xianzhong CHEN1,2,*

- 1. School of Automation and Electrical Engineering, University of Science and Technology Beijing, Beijing 100083, China

2. Key Laboratory of Knowledge Automation for Industrial Processes of Ministry of Education, University of Science and Technology Beijing, Beijing 100083, China

-

Received:2021-08-23Online:2023-04-21Published:2023-04-28 -

Contact:Xianzhong CHEN

CLC Number:

Cite this article

Qing YU, Qingwen HOU, Xianzhong CHEN. Scattering characteristics modeling and imaging of blast furnace burden surface in dusty environment[J]. Systems Engineering and Electronics, 2023, 45(5): 1277-1285.

share this article

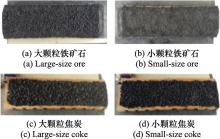

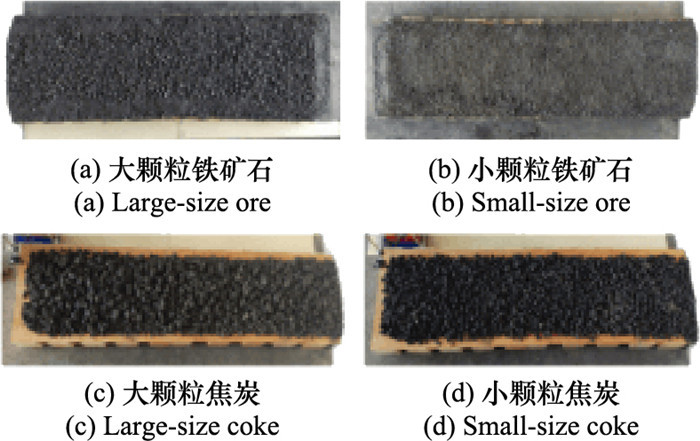

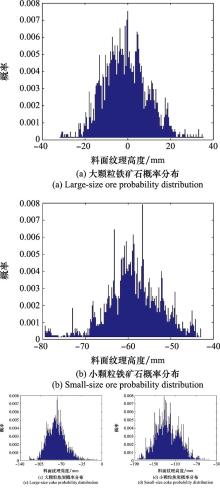

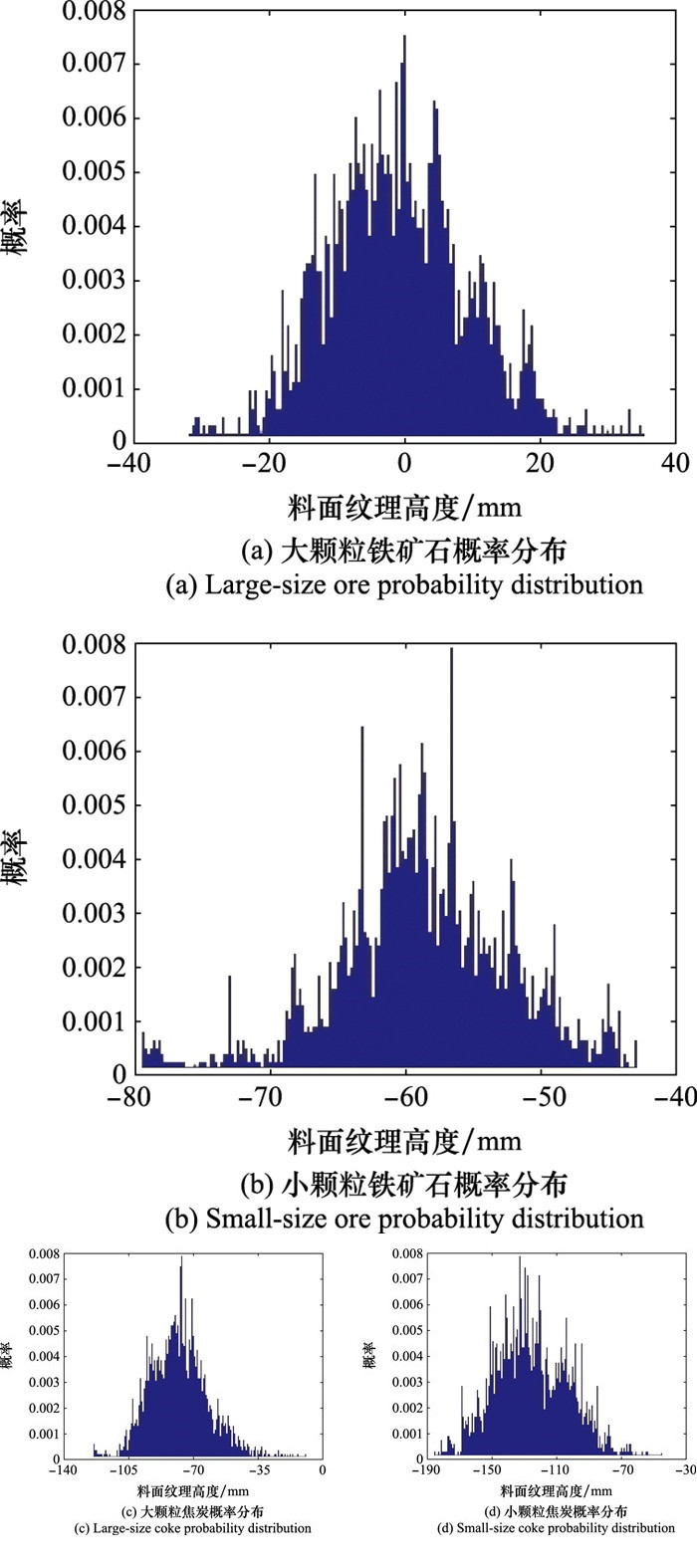

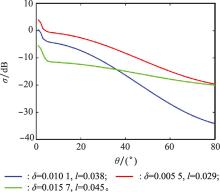

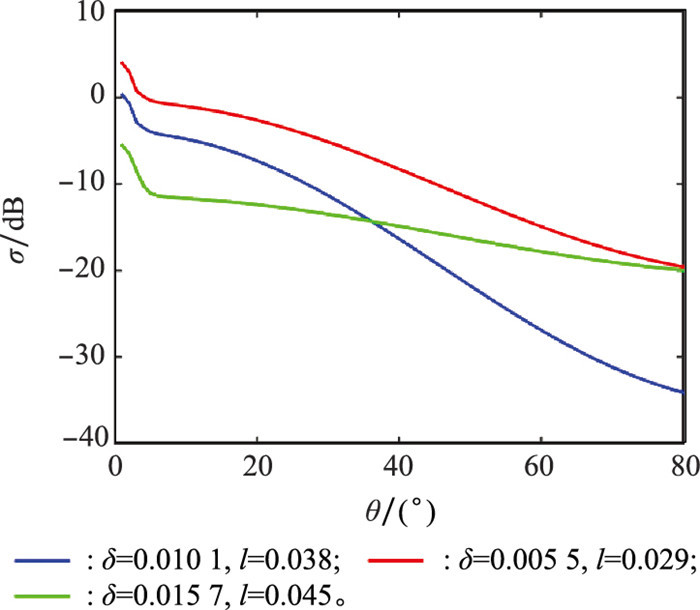

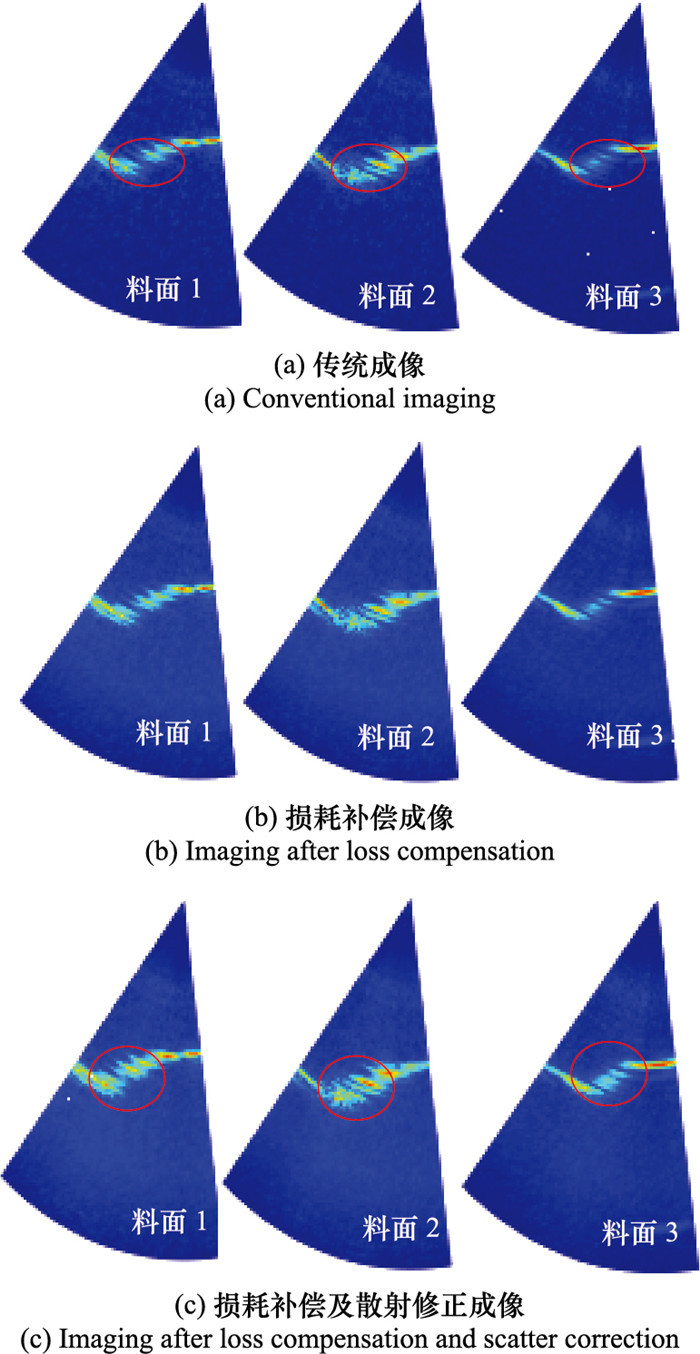

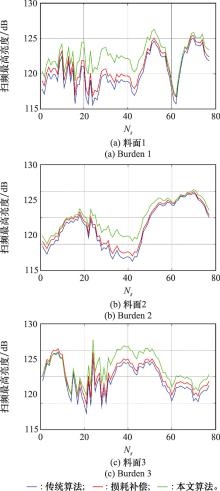

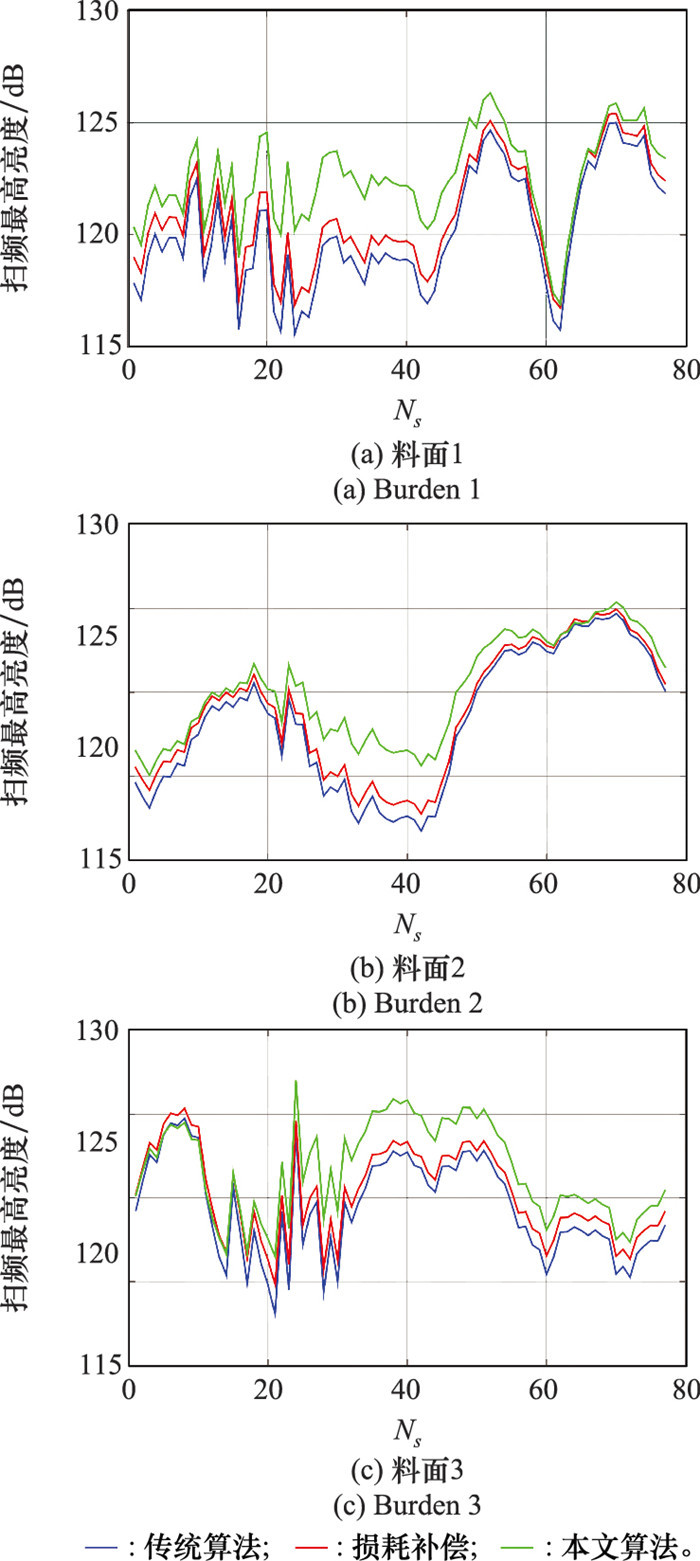

Table 3

Burden surface roughness parameters and coefficients of geometric model"

| 算例 | 料批 | 粗糙度参数/m | 几何模型系数(炉径=4.6 m) |

| 料面1 | 小颗粒 矿石 | δ=0.005 5, l=0.029 | a1=-0.47, b1=-5.12 a2=0.16, b2=-0.03, c2=-5.69 a3=0.12, b3=-5.24 |

| 料面2 | 大颗粒 矿石 | δ=0.010 1, l=0.038 | a1=-0.68, b1=-5.05 a2=0.56, b2=-1.55, c2=-4.71 a3=0.25, b3=-6.01 |

| 料面3 | 小颗粒 焦炭 | δ=0.015 7, l=0.045 | a1=-0.54, b1=-4.85 a2=0.59, b2=-1.81, c2=-4.15 a3=0.16, b3=-5.48 |

| 1 | WANG J , LI X , WANG M Z , et al. Theoretical analysis of potential applications of microwave radar for sandstorm detection[J]. Theoretical and Applied Climatology, 2019, 137 (3): 3209- 3214. |

| 2 | DONG Q F , LI Y L , XU J D , et al. Backscattering characteristics of millimeter wave radar in sand and dust storms[J]. Journal of Electromagnetic Waves & Applications, 2014, 28 (9): 1075- 1084. |

| 3 |

DONG Q F , GUO L X , LI Y , et al. Weathering sand and dust storms: particle shapes, storm height, and elevation angle sensitivity for microwave propagation in earth-satellite links[J]. IEEE Antennas and Propagation Magazine, 2017, 59, 58- 65.

doi: 10.1109/MAP.2016.2630031 |

| 4 |

HUANG J C , CHEN Z P , JIANG Z H , et al. 3D topography measurement and completion method of blast furnace burden surface using high-temperature industrial endoscope[J]. IEEE Sensors Journal, 2020, 20 (12): 6478- 6491.

doi: 10.1109/JSEN.2020.2974253 |

| 5 |

WEI J , CHEN X . Blast furnace gas flow strength prediction using FMCW radar[J]. ISIJ International, 2015, 55 (3): 600- 604.

doi: 10.2355/isijinternational.55.600 |

| 6 | CHEN Z P , JIANG Z H , YANG C J , et al. Detection of blast furnace stockline based on a spatial-temporal characteristic cooperative method[J]. IEEE Trans.on Instrumentation and Mea-surement, 2020, 70, 2500213. |

| 7 |

KHAN M I , KHALID Z , TAHIR F A . Linear and circular-polarization conversion in X-band using anisotropic metasurface[J]. Scientific Reports, 2019, 9, 4552.

doi: 10.1038/s41598-019-40793-2 |

| 8 |

RHEE J Y , SHIM J , KEE S H , et al. Different characteristics of radar signal attenuation depending on concrete condition of bare bridge deck[J]. KSCE Journal of Civil Engineering, 2020, 24 (7): 2049- 2062.

doi: 10.1007/s12205-020-1840-1 |

| 9 |

WANG Z M , GUO Q J , TIAN X Z , et al. Near-field 3-D millimeterwave imaging using MIMO RMA with range compensation[J]. IEEE Trans.on Microwave Theory and Techniques, 2019, 67 (3): 1157- 1166.

doi: 10.1109/TMTT.2018.2884409 |

| 10 |

LIANG B Y , SHANG X Z , ZHUGE X D , et al. Accurate near-field millimeter-wave imaging of concave objects—a case study of dihedral structures under monostatic array configurations[J]. IEEE Trans.on Geoscience and Remote Sensing, 2020, 58 (5): 3469- 3483.

doi: 10.1109/TGRS.2019.2957315 |

| 11 | LI P , ZHOU F , ZHAO B , et al. A novel large-angle ISAR imaging algorithm based on dynamic scattering model[J]. IEICE Trans.on Electronics, 2020, (10): 524- 532. |

| 12 |

WANG Z M , GUO Q J , TIAN X J , et al. Millimeter-wave image reconstruction algorithm for one-stationary bistatic SAR[J]. IEEE Trans.on Microwave Theory and Techniques, 2020, 68 (3): 1185- 1194.

doi: 10.1109/TMTT.2019.2955126 |

| 13 | SHI Q D , WU J X , NI Z M , et al. A blast furnace burden surface deeplearning detection system based on radar spectrum restructured by entropy weight[J]. IEEE Sensors Journal, 2020, 21 (6): 7928- 7939. |

| 14 |

GOLO V C A , DYCHKOVSKYI R , PAZYNICH Y , et al. Some aspects of the control for the radial distribution of burden material and gas flow in the blast furnace[J]. Energies, 2020, 13 (4): 932.

doi: 10.3390/en13040932 |

| 15 |

ZANKL D , SCHUSTER S , FEGER R , et al. What a blast: a massive MIMO radar system for monitoring the surface in steel industry blast furnaces[J]. IEEE Microwave Magazine, 2017, 18 (6): 52- 69.

doi: 10.1109/MMM.2017.2711998 |

| 16 |

YI Z H , CHEN Z P , JIANG Z H , et al. A novel 3-D high-temperature industrial endoscope with large field depth and wide field[J]. IEEE Trans.on Instrumentation and Measurement, 2020, 69 (9): 6530- 6543.

doi: 10.1109/TIM.2020.2970372 |

| 17 |

CHEN X Z , WEI J D , XU D , et al. 3-dimension imaging system of burden surface with 6-radars array in a blast furnace[J]. ISIJ International, 2012, 52 (11): 2048- 2054.

doi: 10.2355/isijinternational.52.2048 |

| 18 |

WEI J D , CHEN X Z , WANG Z D , et al. 3-dimension burden surface imaging system with T-shaped MIMO radar in the blast furnace[J]. ISIJ International, 2015, 55 (3): 592- 599.

doi: 10.2355/isijinternational.55.592 |

| 19 | 魏纪东, 马金芳, 万雷, 等. 沿高炉料面径向的机械摆动雷达料形测量系统[J]. 钢铁, 2015, 50 (6): 94- 100. |

| WEI J D , MA J F , WAN L , et al. Measuring system of radial burden surface with mechanical swing radar in a blast furnace[J]. Iron & Steel, 2015, 50 (6): 94- 100. | |

| 20 |

BI H , CHENG Y , ZHU D Y , et al. Wavelet-based L regularization for CS-TomoSAR imaging of forested area[J]. Journal of Systems Engineering and Electronics, 2020, 31 (6): 1160- 1166.

doi: 10.23919/JSEE.2020.000088 |

| 21 | PAUL D S , DIVYA S V , PATI U C . Structure tensor based SIFT algorithm for SAR image registration[J]. IET Image Processing, 2019, 14 (5): 929- 938. |

| 22 |

CHEN X , YANG Q , DENG B , et al. A FFT-based millimeter-wave imaging algorithm with range compensation for near-field MIMO-SAR[J]. Journal of Infrared, Millimeter, and Terahertz Waves, 2021, 42 (4): 391- 408.

doi: 10.1007/s10762-021-00786-7 |

| 23 | LI Y I , ZHANG S , ZHANG J , et al. Data-driven multi-objective optimization for burden surface in blast furnace with feedback compensation[J]. IEEE Trans.on Industrial Informatics, 2019, 16 (4): 2233- 2244. |

| 24 |

LIU Y Z , XU X J , XU G Y . MIMO radar calibration and imagery for near-field scattering diagnosis[J]. IEEE Trans.on Aerospace and Electronic Systems, 2018, 54 (1): 442- 452.

doi: 10.1109/TAES.2017.2760758 |

| 25 |

KAMAL S , MANI K , ADIB Y , et al. A polarimetric active transponder with extremely large RCS for absolute radiometric calibration of SMAP radar[J]. IEEE Trans.on Geoscience and Remote Sensing, 2018, 56 (3): 1269- 1277.

doi: 10.1109/TGRS.2017.2745206 |

| 26 | 欧湛, 郑小平, 耿华. 粗糙面散射对太赫兹雷达成像的影响[J]. 清华大学学报(自然科学版), 2019, 59 (5): 388- 393. |

| OU Z , ZHENG X P , GENG H . Effects of rough surface scattering on terahertz radar imaging[J]. Journal of Tsinghua University (Science and Technology), 2019, 59 (5): 388- 393. | |

| 27 |

WEI G C , ZHANG H , AN X Z , et al. CFD-DEM study on heat transfer characteristics and microstructure of the blast furnace raceway with ellipsoidal particles[J]. Powder Technology, 2019, 346, 350- 362.

doi: 10.1016/j.powtec.2019.02.022 |

| 28 | 张浙东, 黎鑫, 张金鹏, 等. 基于姿态修正的目标RCS动态测量方法[J]. 系统工程与电子技术, 2019, 41 (6): 1242- 1248. |

| ZHANG Z P , LI X , ZHANG J P , et al. Dynamic measurement method of target RCS based on attitude correction[J]. Systems Engineering and Electronics, 2019, 41 (6): 1242- 1248. | |

| 29 |

TSANG L , DING K , HUANG S , et al. Electromagnetic computation in scattering of electromagnetic waves by random rough surface and dense media in microwave remote sensing of land surfaces[J]. Proceedings of the IEEE, 2013, 101 (2): 255- 279.

doi: 10.1109/JPROC.2012.2214011 |

| 30 | TIAN J , TANAKA A , MENG Y , et al. Tracking the burden surface radial profile of a blast furnace by a B-mode mechanical swing radar system[J]. ISIJ International, 2019, 60 (2): 297- 307. |

| 31 |

OLSON D R , JACKSON D . Scattering from layered seafloors: comparisons between theory and integral equations[J]. The Journal of the Acoustical Society of America, 2020, 148 (4): 2086- 2095.

doi: 10.1121/10.0002164 |

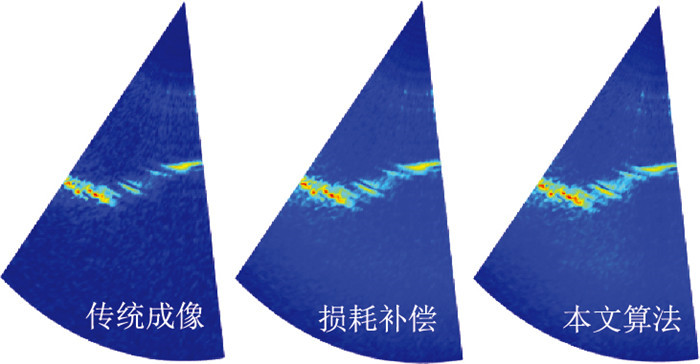

| 32 | 陈相兵, 倪梓明, 陈先中, 等. 高炉燃烧料面合成孔径雷达双聚焦成像算法[J]. 控制理论与应用, 2020, 37 (8): 1826- 1836. |

| CHEN X B , NI Z M , CHEN X Z , et al. Dual-focus imaging algorithm of synthetic aperture radar for burning blast furnace burden surface[J]. Control Theory & Applications, 2020, 37 (8): 1826- 1836. |

| [1] | Ling GUAN, Chenxi ZHU, Chunzhu DONG, Hongcheng YIN. Fast analysis of electromagnetic characteristics for UAV groups based on mode and domain decomposition [J]. Systems Engineering and Electronics, 2021, 43(10): 2697-2705. |

| [2] | Ping HAN, Bo ZHOU, Bin LU, Binbin HAN. Aircraft target detection of PolSAR based on the fusion of environmental feature and scattering characteristics [J]. Systems Engineering and Electronics, 2020, 42(10): 2231-2238. |

| [3] | HAN Ping, JIA Kun, LU Xiaoguang, HAN Binbin. Improved non-local mean filtering method for PolSAR images [J]. Systems Engineering and Electronics, 2019, 41(5): 992-999. |

| [4] | . Review of controllable method of electromagnetic scattering characteristics of passive scattering elements [J]. Systems Engineering and Electronics, 2019, 41(4): 716-723. |

| [5] | LI Jianzhou, LIU Xiangwei, FAN Chaoqun, LIU Lu, QI Yutao. Geometric modeling and scattering characteristics analysis of multi-degree-of-freedom flying targets [J]. Systems Engineering and Electronics, 2019, 41(11): 2401-2407. |

| [6] | GAO Xiaoguang, LI Fei, WAN Kaifang. Research on multi-sensor cooperative tracking strategy in data packet loss environment [J]. Systems Engineering and Electronics, 2018, 40(11): 2450-. |

| [7] | YAN Pei-wen, TONG Chuang-ming, JI Wei-jie. Fast computation of electromagnetic scattering characteristics for 2-D fractal rough surface by SMFSIA/CAG [J]. Journal of Systems Engineering and Electronics, 2009, 31(9): 2117-2120. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||